VARILEX® Speed-Controlled Angle Grinder & Flap Discs

VARILEX® Speed-Controlled Angle Grinder & Flap Discs

| Thanks to the new EASY-LOCK clamping nut, abrasives can now be changed in seconds without any tools. The EASY-LOCK clamping nut will work with any abrasive with a hemp or ABS backing plate and a 7/8” arbor. That means you can change any CS Unitec/Eisenblatter abrasive on an angle grinder in a matter of seconds using this uniquely simple solution. The clamping collar shaped on the top of the EASY-LOCK clamping nut can secure flap discs and abrasives with a “thicker” backing disc as well as centering them. “Thin” abrasives such as cutting discs, etc. can simply be secured using the reverse of the EASY-LOCK clamping nut.  1. Secure the disc loosely by hand using the EASY-LOCK clamping nut. 2. Press the spindle lock and tighten the disc by turning it clockwise by hand. That’s all there is to it! 3. To release the disc, press the spindle lock and turn the disc counter-clockwise by hand. |

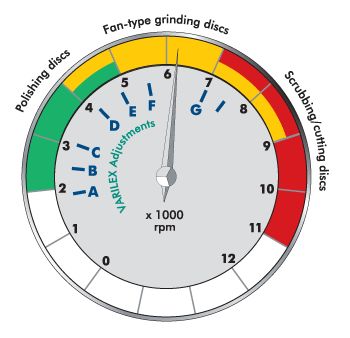

Recommended speeds for maximum flap disc service life and economy: 4” diameter: 9000 – 11,000 RPM |

| Obtaining good polish quality when finishing corner welds is difficult, especially for the fabrication of railings. The POLY-MAGIC-WHEEL was designed to help you more easily produce a truly perfect finish in these applications. This highly compacted fleece disc was designed specifically for grinding and polishing bead and corner welds. The POLY-MAGIC-WHEEL disc can reduce the time required for this work to a minimum, and the result can only be described as a minor miracle. Carry out the initial grinding and leveling of welds with the red disc, grit A (80 grit). Then polish to a mirror finish using the POLY-MAGIC gray disc, grit B (900 grit). These discs are very aggressive; they save a lot of working time and the result is sensational. No polishing compounds or creams are required for polishing with the POLY-MAGICWHEEL (dry polish). Mirror finish in 2 steps: POLY-MAGIC-WHEEL

A (80 grit)  POLY-MAGIC-WHEEL

B (900 grit)  |

Pre-grinding to remove scratches and level welds using TZ Pyramid discs with grit A30. Fine grinding using TZ Pyramid discs with grit A16. These two stages prepare the surface for polishing. TZ Pyramid is an aggressive abrasive, so there is no need to slowly increase the grit fineness. Use only contact pressure to grind – the weight of the grinder is generally sufficient. Pre-polish with SuperPolish disc and white polishing compound. |

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details