TwinMix 1800 Portable Automatic Mixing Station

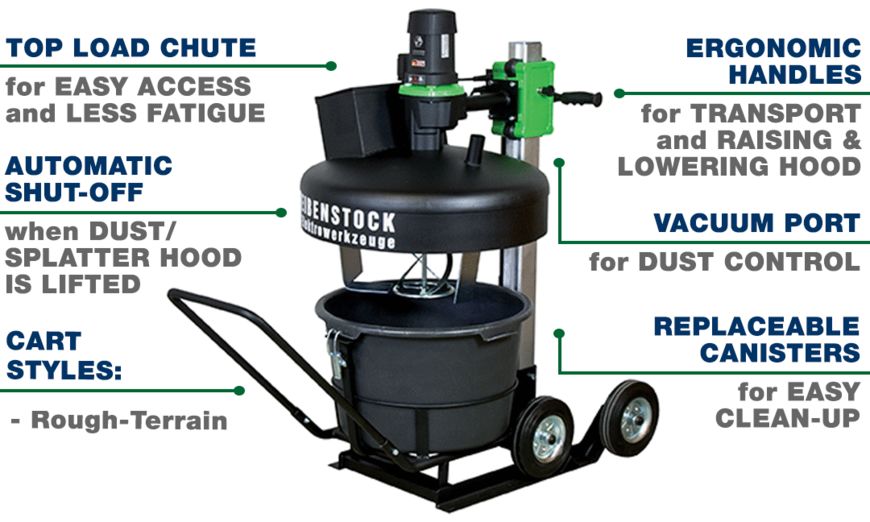

Reduce Dust While Adding and Mixing Medium- to High-viscosity Materials

- Up to 2000 lbs. of production output per hour

- Optional timer and second cart cuts labor and production time in half – one user can mix a new batch while pouring the previous batch!

- Ideal for mixing heavy and trowel urethanes, brick and heavy mortar, filler and leveling compounds, plaster, thin-bed mortars and other high-viscosity materials

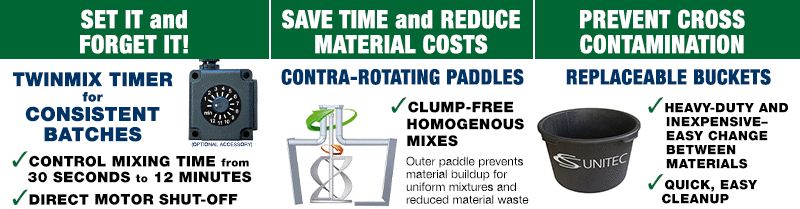

- Two contra-rotating paddles thoroughly combine compounds into a homogeneous, lump-free mixture

- Dust extraction port collects dust while adding materials and mixing

Unique Features Improve Productivity and Reduce User Fatigue:

Make the tough, often time-consuming process of mixing high-viscosity materials easy with the TwinMix 1800 TFR portable mixing station. This mixing station streamlines the blending of materials with a medium to high thickness while protecting against dust and other contaminants.

Additional features of the TwinMix 1800 TFR include:

- Timer for automatic mixing

- Dual mixing paddle with scraper

- Replaceable liners for easy cleanup and prevention of cross contamination

- Dust extraction port for connection to industrial vacuum

- Front Pouring cart

- Brush-lined inlet tube for dust containment

- Ergonomic handles and large wheels for easy mobility

- Safety switch disables motor when hood is lifted during mixing

- Transport carts and buckets can also be used with handheld mixer

Cut Labor & Production Time IN HALF with a Timer and Extra Cart!One User can Mix a New Batch While Pouring the Previous Batch |  |

How the TWINMIX Will Improve Mix Results and Save $$:

The robust two-speed, 15-amp motor is built in Germany and designed to outlast and outperform. A provided canister cover and dust extraction port reduce airborne dust and splatter. Also, the pouring cart enables workers to perform clean, accurate pours. Continuous batch mixing is possible with the addition of one or more extra carts.

- Specifications

- Video

- Standard Equipment

- Applications

- ACCESSORIES

| Model | Twinmix 1800 TFR |

|---|---|

| Power | 15 AMP / 110 V |

| Bucket Capacity | 17 gallons |

| Helical Rod Speed | 250 / 450 RPM |

| Scraper Paddle Speed | 20 / 36 RPM |

| Weight | 155 lbs. |

| Timer (Included) | P/N 32353000 |

Standard equipment includes:

- Timer (P/N 32353000)

- Motor on stand

- Mixing rod (inner helical paddle, P/N 31452)

- Mixing paddle (outer paddle, P/N 31451)

- Mixing bucket (P/N 32341)

- Front Pouring cart (P/N 32333000)

|  |  |

| Thin-bed mortar | Masonry mortar | Plasters |

|  |  |

| Floating screed | Tile cement | Grout |

|  |  |

| Insulation board adhesive | Screed | Filler |

| Timer P/N 32353000 (Included) |  |

| 17 Gal. Replacement Bucket (Tub) Order No: 32341 |  |

Big Wheel Transportation Cart:

Order No: 32333000 Description: Front Tip transport cart with 2 large wheels |  |

| Shortcuts: | Downloads: |

|---|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details