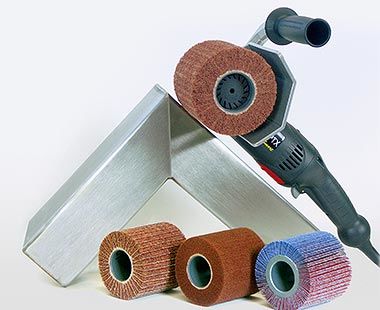

Metal Surface Finishing Tools & Polishing Machines

CS Unitec offers professional power tools and abrasive accessories, including metal polish machines, for surface finishing on steel, stainless steel, aluminum and other metals, as well as rigid plastics and wood. The value is in the engineering... the payback is in the performance.™

For technical questions/purchasing information about metal surfacing machines and tools for polishing metal, call 1-800-700-5919 (USA/Canada) or +1 (203) 853-9522 (International).

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details