PLANTEX® Flap Discs

Industry First Technology & Superior Performance

Our updated, cutting-edge, environmentally friendly Flap Discs are designed for high-performance & efficiency. These flap discs are more impact resistant versus fiberglass, absorb heat and sounds, are usable down to the backing, and are made with industrial protected hemp backing! Our new line consists of the PLANTEX® Sunfire, PLANTEX® SpitFire, PLANTEX® Weld-Ex, and PLANTEX® Aluminum. Our range of Flap Discs can handle even the toughest applications, and are built to excel on a wide range of surfaces. To learn more, please call 203-853-9522 or contact us here.

Longer, faster, and better grinding

- Irregular grinding

- Poor grinding capacity

- Short service life

- Potential flap tearing

Ceramic-Hybrid

- For use on stainless steel, carbon steel, & heat sensitive alloys

- Fast cut & long-life

- Type 29

Premium Zirconia

- For use on carbon steel & stainless steel

- High removal rates & long life

- Type 29

Zirconia

- For use on carbon steel & stainless steel

- Overhang excels for corners & tight areas

- Fast cut & long-life

- Type 29

Aluminum

- Grind & blend aluminum & other non-ferrous materials

- Minimizes loading & providing long-life

- Type 29

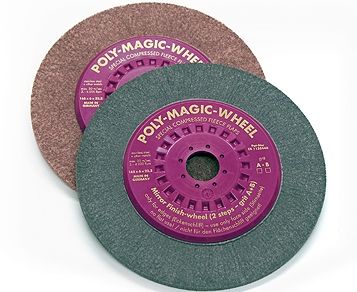

Pore-deep cleaning of metals

- Iron-free – no risk of corrosion

- Coarse fleece interspersed with silicon carbide grit

- Clean without harming base material

Foamed and compressed fleece combination offers:

- Increased material removal

- Excellent service life

- Easy deburring & cleaning

Spray for aluminum workpiece grinding:

- Improve removal rate

- Increase abrasive life

Last 100x longer than ordinary resin bonded wheels

- Reduce sparks, dust and material waste

- Save time changing discs

- Ideal for grinding and cutting steel, stainless steel, aluminum, titanium, fiberglass and more

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details