Pipe Cutter

Ex1512 Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

- Non-sparking pipe cutter for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic pipe cutter for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant pipe cutter for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- ALLOYS & USE

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex1512-60A | Ex1512-60B |

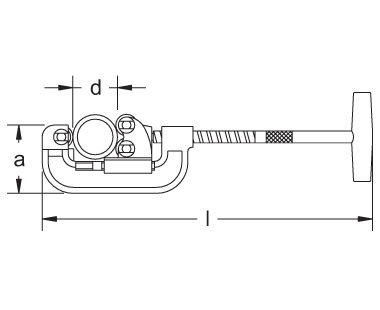

| No. | a inch | d max inch | l inch | Wt. lbs. | a mm | d max mm | l mm | Wt. kg |

|---|---|---|---|---|---|---|---|---|

| Ex1512-60 | 3-11/16 | 2-3/8 | 17-3/4 | 7.21 | 92 | 60 | 445 | 3.27 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

For More Information on Choosing The Correct Alloy for Your Application - Click Here

| Proper Use | Misuse |

| Pipe cutter wheels that are nicked or otherwise damaged should be replaced. When removing, rapid spinning of the die threading stock is not recommended as this may damage the tool. Be certain the cutting wheel is suitable to cut type of pipe material. Thin wheel is suitable for cutting ordinary steel pipe, stout wheel is made to cut cast iron. Other wheels are available for stainless steel, plastic and other materials. | If there is not enough space to swing the single wheel pipe cutter completely around pipe, then a three or four-wheel cutter should be used. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details