Combination Wrenches

Ex206 and 206L Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking combination wrench for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic combination wrench for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant combination wrench for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard

- Metric

- Long - Standard

- Long - Metric

- Alloys & Use

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex206-005UA | Ex206-005UB |

| Ex206L-005UA | Ex206L-005UB |

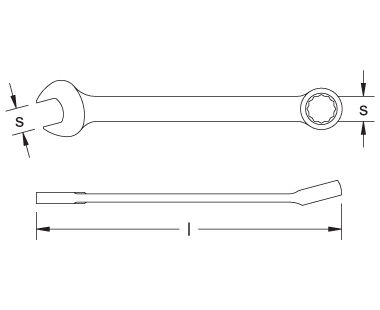

| No. | S inch | l inch | Wt. lbs. |

|---|---|---|---|

| Ex206-005U | 1/4 | 3-9/16 | 0.05 |

| Ex206-010U | 5/16 | 4-3/16 | 0.07 |

| Ex206-015U | 11/32 | 4-9/16 | 0.10 |

| Ex206-020U | 3/8 | 4-9/16 | 0.10 |

| Ex206-025U | 13/32 | 5-3/8 | 0.15 |

| Ex206-030U | 7/16 | 5-3/8 | 0.15 |

| Ex206-035U | 1/2 | 6 | 0.22 |

| Ex206-040U | 9/16 | 6-3/8 | 0.29 |

| Ex206-045U | 19/32 | 6-3/8 | 0.29 |

| Ex206-050U | 5/8 | 7 | 0.33 |

| Ex206-055U | 11/16 | 7-3/16 | 0.37 |

| Ex206-060U | 3/4 | 8-3/16 | 0.51 |

| Ex206-065U | 25/32 | 8-3/16 | 0.51 |

| Ex206-070U | 13/16 | 9-3/16 | 0.60 |

| Ex206-075U | 7/8 | 9-3/4 | 0.66 |

| Ex206-080U | 15/16 | 10-9/16 | 0.90 |

| Ex206-085U | 31/32 | 11-9/16 | 1.28 |

| Ex206-090U | 1 | 11-9/16 | 1.28 |

| Ex206-095U | 1-1/16 | 11-9/16 | 1.28 |

| Ex206-100U | 1-1/8 | 12-3/4 | 1.39 |

| Ex206-105U | 1-3/16 | 12-3/4 | 1.39 |

| Ex206-110U | 1-1/4 | 13-3/8 | 1.74 |

| Ex206-115U | 1-5/16 | 14 | 2.03 |

| Ex206-120U | 1-3/8 | 14 | 2.03 |

| Ex206-125U | 1-7/16 | 14 | 2.03 |

| Ex206-130U | 1-1/2 | 14-3/8 | 2.73 |

| Ex206-135U | 1-9/16 | 14-3/4 | 3.22 |

| Ex206-140U | 1-5/8 | 14-3/4 | 3.22 |

| Ex206-145U | 1-11/16 | 16-3/16 | 3.70 |

| Ex206-150U | 1-3/4 | 16-3/16 | 3.70 |

| Ex206-155U | 1-13/16 | 16-3/16 | 3.70 |

| Ex206-160U | 1-7/8 | 16-3/16 | 3.70 |

| Ex206-165U | 2 | 16-3/4 | 4.23 |

| Ex206-170U | 2-3/16 | 17-3/8 | 5.11 |

| Ex206-175U | 2-3/8 | 18-9/16 | 5.71 |

| Ex206-180U | 2-9/16 | 18-3/4 | 6.35 |

| Ex206-185U | 2-3/4 | 19-3/16 | 7.47 |

| Ex206-190U | 2-5/8 | 19-3/16 | 7.47 |

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex206-005UA | Ex206-005UB |

| Ex206L-005UA | Ex206L-005UB |

| No. | s mm | l mm | Wt. kg |

|---|---|---|---|

| Ex206-6 | 6 | 90 | 0.02 |

| Ex206-7 | 7 | 100 | 0.03 |

| Ex206-8 | 8 | 105 | 0.03 |

| Ex206-9 | 9 | 115 | 0.05 |

| Ex206-10 | 10 | 125 | 0.05 |

| Ex206-11 | 11 | 135 | 0.07 |

| Ex206-12 | 12 | 140 | 0.09 |

| Ex206-13 | 13 | 150 | 0.10 |

| Ex206-14 | 14 | 160 | 0.13 |

| Ex206-15 | 15 | 165 | 0.14 |

| Ex206-16 | 16 | 175 | 0.15 |

| Ex206-17 | 17 | 180 | 0.17 |

| Ex206-18 | 18 | 195 | 0.21 |

| Ex206-19 | 19 | 205 | 0.23 |

| Ex206-20 | 20 | 205 | 0.25 |

| Ex206-21 | 21 | 230 | 0.27 |

| Ex206-22 | 22 | 245 | 0.30 |

| Ex206-23 | 23 | 245 | 0.36 |

| Ex206-24 | 24 | 265 | 0.41 |

| Ex206-25 | 25 | 290 | 0.58 |

| Ex206-26 | 26 | 290 | 0.58 |

| Ex206-27 | 27 | 290 | 0.58 |

| Ex206-28 | 28 | 320 | 0.63 |

| Ex206-30 | 30 | 320 | 0.63 |

| Ex206-32 | 32 | 335 | 0.79 |

| Ex206-34 | 34 | 350 | 0.92 |

| Ex206-36 | 36 | 350 | 0.93 |

| Ex206-38 | 38 | 360 | 1.24 |

| Ex206-41 | 41 | 370 | 1.46 |

| Ex206-46 | 46 | 405 | 1.68 |

| Ex206-50 | 50 | 420 | 1.92 |

| Ex206-55 | 55 | 435 | 2.32 |

| Ex206-60 | 60 | 465 | 2.59 |

| Ex206-65 | 65 | 470 | 2.88 |

| Ex206-70 | 70 | 480 | 3.39 |

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex206-005UA | Ex206-005UB |

| Ex206L-005UA | Ex206L-005UB |

| No. | S inch | l inch | Wt. lbs. |

|---|---|---|---|

| Ex206L-005U | 1/4 | 5.91 | 0.11 |

| Ex206L-010U | 5/16 | 5.91 | 0.11 |

| Ex206L-015U | 11/32 | 5.91 | 0.11 |

| Ex206L-020U | 3/8 | 5.91 | 0.11 |

| Ex206L-025U | 13/32 | 6.89 | 0.17 |

| Ex206L-030U | 7/16 | 6.89 | 0.17 |

| Ex206L-035U | 1/2 | 8.07 | 0.25 |

| Ex206L-040U | 9/16 | 8.07 | 0.25 |

| Ex206L-045U | 19/32 | 8.86 | 0.32 |

| Ex206L-050U | 5/8 | 8.86 | 0.32 |

| Ex206L-055U | 11/16 | 10.63 | 0.57 |

| Ex206L-060U | 3/4 | 10.63 | 0.57 |

| Ex206L-065U | 25/32 | 11.61 | 0.66 |

| Ex206L-070U | 13/16 | 11.61 | 0.66 |

| Ex206L-075U | 7/8 | 11.61 | 0.66 |

| Ex206L-080U | 15/16 | 12.80 | 0.88 |

| Ex206L-085U | 31/32 | 12.80 | 0.88 |

| Ex206L-090U | 1 | 13.98 | 1.21 |

| Ex206L-095U | 1-1/16 | 13.98 | 1.21 |

| Ex206L-100U | 1-1/8 | 15.35 | 1.52 |

| Ex206L-105U | 1-3/16 | 15.35 | 1.52 |

| Ex206L-110U | 1-1/4 | 16.93 | 2.20 |

| Ex206L-115U | 1-5/16 | 16.93 | 2.20 |

| Ex206L-120U | 1-3/8 | 18.70 | 2.43 |

| Ex206L-125U | 1-7/16 | 18.70 | 2.43 |

| Ex206L-130U | 1-1/2 | 18.70 | 2.43 |

| Ex206L-135U | 1-9/16 | 20.67 | 3.20 |

| Ex206L-140U | 1-5/8 | 20.67 | 3.20 |

| Ex206L-145U | 1-11/16 | 22.64 | 4.19 |

| Ex206L-150U | 1-3/4 | 22.64 | 4.19 |

| Ex206L-155U | 1-13/16 | 22.64 | 4.41 |

| Ex206L-160U | 1-7/8 | 22.64 | 4.41 |

| Ex206L-161U | 1-15/16 | 22.64 | 4.63 |

| Ex206L-162U | 1-15/16 | 22.64 | 4.63 |

| Ex206L-165U | 2 | 22.64 | 4.85 |

| Ex206L-167U | 2-1/16 | 22.64 | 4.85 |

| Ex206L-168U | 2-1/8 | 22.64 | 5.73 |

| Ex206L-170U | 2-3/16 | 22.64 | 5.73 |

| Ex206L-172U | 2-1/4 | 22.64 | 5.73 |

| Ex206L-173U | 2-5/16 | 22.64 | 6.94 |

| Ex206L-175U | 2-3/8 | 22.64 | 6.94 |

| Ex206L-177U | 2-7/16 | 22.64 | 6.94 |

| Ex206L-178U | 2-1/12 | 22.64 | 10.10 |

| Ex206L-180U | 2-9/16 | 22.64 | 6.35 |

| Ex206L-185U | 2-5/8 | 22.64 | 7.47 |

| Ex206L-187U | 2-11/16 | 22.64 | |

| Ex206L-190U | 2-3/4 | 22.64 | 7.47 |

| Ex206L-205U | 2-13/16 | 25 | |

| Ex206L-210U | 2-7/8 | 25 | |

| Ex206L-215U | 2-15/16 | 25 | |

| Ex206L-220U | 3 | 25 | |

| Ex206L-230U | 3-1/8 | 25 |

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex206-005UA | Ex206-005UB |

| Ex206L-005UA | Ex206L-005UB |

| No. | s mm | l mm | Wt. kg |

|---|---|---|---|

| Ex206L-6 | 6 | 120 | 0.03 |

| Ex206L-7 | 7 | 120 | 0.03 |

| Ex206L-8 | 8 | 150 | 0.05 |

| Ex206L-9 | 9 | 150 | 0.05 |

| Ex206L-10 | 10 | 175 | 0.05 |

| Ex206L-11 | 11 | 175 | 0.08 |

| Ex206L-12 | 12 | 205 | 0.12 |

| Ex206L-13 | 13 | 205 | 0.12 |

| Ex206L-14 | 14 | 205 | 0.12 |

| Ex206L-15 | 15 | 225 | 0.15 |

| Ex206L-16 | 16 | 225 | 0.15 |

| Ex206L-17 | 17 | 270 | 0.26 |

| Ex206L-18 | 18 | 270 | 0.26 |

| Ex206L-19 | 19 | 270 | 0.26 |

| Ex206L-20 | 20 | 295 | 0.30 |

| Ex206L-21 | 21 | 295 | 0.30 |

| Ex206L-22 | 22 | 295 | 0.30 |

| Ex206L-23 | 23 | 325 | 0.40 |

| Ex206L-24 | 24 | 325 | 0.40 |

| Ex206L-25 | 25 | 355 | 0.55 |

| Ex206L-26 | 26 | 355 | 0.55 |

| Ex206L-27 | 27 | 355 | 0.55 |

| Ex206L-28 | 28 | 390 | 0.69 |

| Ex206L-29 | 29 | 390 | 0.69 |

| Ex206L-30 | 30 | 390 | 0.69 |

| Ex206L-31 | 31 | 390 | 0.69 |

| Ex206L-32 | 32 | 430 | 1.00 |

| Ex206L-33 | 33 | 430 | 1.00 |

| Ex206L-34* | 34 | 430 | 1.00 |

| Ex206L-35 | 35 | 430 | 1.00 |

| Ex206L-36 | 36 | 475 | 1.10 |

| Ex206L-38 | 38 | 475 | 1.10 |

| Ex206L-40 | 40 | 475 | 1.10 |

| Ex206L-41 | 41 | 525 | 1.45 |

| Ex206L-42 | 42 | 525 | 1.45 |

| Ex206L-46 | 46 | 550 | 1.90 |

| Ex206L-47 | 47 | 550 | 1.90 |

| Ex206L-48 | 48 | 550 | 1.90 |

| Ex206L-50 | 50 | 575 | 2.20 |

| Ex206L-55 | 55 | 575 | 2.60 |

| Ex206L-60 | 60 | 575 | 3.15 |

| Ex206L-65 | 65 | 575 | 4.58 |

| Ex206L-70 | 70 | 575 | 4.58 |

| Ex206L-75 | 75 | 635 | 5.80 |

| Ex206L-80 | 80 | 635 | 5.80 |

*AlBr Only

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

For More Information on Choosing The Correct Alloy for Your Application - Click Here

| Proper Use | Misuse |

| Combination Box/Open-End wrenches are designed for a wide variety of work. Their box opening adds more to their versatility and strength. The Flare Nut pattern with its hex box opening is especially useful in air conditioning and refrigeration work where tubing terminates on flare nuts. The thinner and slimmer pattern is designed for work where access and clearance are limited | Do not use the open end of these wrenches to free a "frozen" nut or final tighten a hex nut. Use the box opening. Never use an extension on the wrench handle. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details