Deep Sockets, 6-Point, 3/4" Drive

Ex1640 Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking deep sockets for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic deep sockets for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant deep sockets for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- Metric Sizes

- Alloys & Use

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex1640-005UA | Ex1640-005UB |

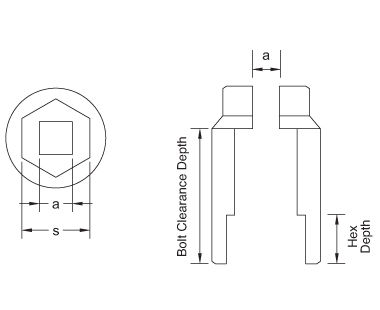

| No. | a inch | s inch | Bolt Clearance Depth Inch | Hex Depth Inch |

|---|---|---|---|---|

| Ex1640-005U | 3/4 | 3/4 | 2.67 | 1.02 |

| Ex1640-010U | 3/4 | 13/16 | 2.67 | 1.02 |

| Ex1640-015U | 3/4 | 7/8 | 2.67 | 1.02 |

| Ex1640-020U | 3/4 | 15/16 | 2.67 | 1.02 |

| Ex1640-025U | 3/4 | 1 | 2.56 | 1.10 |

| Ex1640-030U | 3/4 | 1-1/16 | 2.56 | 1.10 |

| Ex1640-035U | 3/4 | 1-1/8 | 2.56 | 1.10 |

| Ex1640-040U | 3/4 | 1-3/16 | 2.56 | 1.10 |

| Ex1640-045U | 3/4 | 1-1/4 | 2.56 | 1.10 |

| Ex1640-050U | 3/4 | 1-5/16 | 2.56 | 1.10 |

| Ex1640-055U | 3/4 | 1-3/8 | 2.56 | 1.10 |

| Ex1640-060U | 3/4 | 1-7/16 | 2.95 | 1.26 |

| Ex1640-065U | 3/4 | 1-1/2 | 2.87 | 1.26 |

| Ex1640-070U | 3/4 | 1-9/16 | 2.87 | 1.26 |

| Ex1640-075U | 3/4 | 1-5/8 | 2.87 | 1.26 |

| Ex1640-080U | 3/4 | 1-11/16 | 2.87 | 1.26 |

| Ex1640-085U | 3/4 | 1-3/4 | 2.87 | 1.26 |

| Ex1640-090U | 3/4 | 1-13/16 | 2.87 | 1.26 |

| Ex1640-095U | 3/4 | 1-7/8 | 2.87 | 1.26 |

| Ex1640-100U | 3/4 | 1-15/16 | 2.87 | 1.26 |

| Ex1640-105U | 3/4 | 2 | 2.87 | 1.26 |

| Ex1640-110U | 3/4 | 2-1/16 | 2.87 | 1.26 |

| Ex1640-115U | 3/4 | 2-1/8 | 2.87 | 1.26 |

| Ex1640-120U | 3/4 | 2-3/16 | 2.87 | 1.26 |

| Ex1640-125U | 3/4 | 2-1/4 | 2.87 | 1.26 |

| Ex1640-130U | 3/4 | 2-5/16 | 2.87 | 1.26 |

| Ex1640-135U | 3/4 | 2-3/8 | 2.87 | 1.26 |

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex1640-19A | Ex1640-19B |

| No. | a inch | s mm | Bolt Clearance Depth mm | Hex Depth mm |

|---|---|---|---|---|

| Ex1640-19 | 3/4 | 19 | 68 | 26 |

| Ex1640-20 | 3/4 | 20 | 68 | 26 |

| Ex1640-21 | 3/4 | 21 | 68 | 26 |

| Ex1640-22 | 3/4 | 22 | 68 | 26 |

| Ex1640-23 | 3/4 | 23 | 68 | 26 |

| Ex1640-24 | 3/4 | 24 | 65 | 28 |

| Ex1640-25 | 3/4 | 25 | 65 | 28 |

| Ex1640-26 | 3/4 | 26 | 65 | 28 |

| Ex1640-27 | 3/4 | 27 | 65 | 32 |

| Ex1640-28 | 3/4 | 28 | 65 | 32 |

| Ex1640-29 | 3/4 | 29 | 65 | 32 |

| Ex1640-30 | 3/4 | 30 | 65 | 32 |

| Ex1640-31 | 3/4 | 31 | 65 | 32 |

| Ex1640-32 | 3/4 | 32 | 65 | 32 |

| Ex1640-33 | 3/4 | 33 | 65 | 32 |

| Ex1640-34 | 3/4 | 34 | 65 | 32 |

| Ex1640-35 | 3/4 | 35 | 65 | 32 |

| Ex1640-36 | 3/4 | 36 | 65 | 32 |

| Ex1640-37 | 3/4 | 37 | 73 | 32 |

| Ex1640-38 | 3/4 | 38 | 73 | 32 |

| Ex1640-39 | 3/4 | 39 | 73 | 32 |

| Ex1640-40 | 3/4 | 40 | 73 | 32 |

| Ex1640-41 | 3/4 | 41 | 73 | 32 |

| Ex1640-42 | 3/4 | 42 | 73 | 32 |

| Ex1640-43 | 3/4 | 43 | 73 | 32 |

| Ex1640-44 | 3/4 | 44 | 73 | 32 |

| Ex1640-45 | 3/4 | 45 | 73 | 32 |

| Ex1640-46 | 3/4 | 46 | 73 | 32 |

| Ex1640-47 | 3/4 | 47 | 73 | 32 |

| Ex1640-48 | 3/4 | 48 | 73 | 32 |

| Ex1640-49 | 3/4 | 49 | 73 | 32 |

| Ex1640-50 | 3/4 | 50 | 73 | 32 |

| Ex1640-52 | 3/4 | 52 | 73 | 32 |

| Ex1640-55 | 3/4 | 55 | 73 | 32 |

| Ex1640-60 | 3/4 | 60 | 73 | 32 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

| Proper Use | Misuse |

| Socket wrenches are made in a wide range of sizes and capacities. All have square drives ranging from 1/4" to 1". Drive size is a measure of capacity. Since Detachable Socket wrenches provide an almost endless combination of handles, attachments and sockets, it is possible to assemble a proper tool for almost any type of service within the tool's capacity. | Never use a pipe extension or other form of "cheater" to increase the leverage of any wrench. Select a wrench whose opening exactly fits the nut. If possible, always pull on a wrench handle and adjust your stance to prevent a fall if something lets go. There are three types of Sockets hand, power and impact all different in design and hardness. Hand Sockets should never be used on power drive or impact wrenches. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details