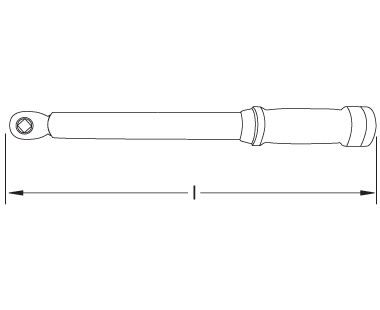

Non Sparking Torque Wrench - 1/2" Drive

CuBe Torque Wrench - Ex1401

- Non-Sparking

- Corrosion Resistant

- Non-Magnetic

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking torque wrench for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic torque wrench for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant torque wrench for use in desalination plants, chemical/paper manufacturing, and shipyards.

Make your workplace safe with the right non-sparking safety tools. The CuBe torque wrench is a non-sparking torque wrench designed for low torque tightening and tapping by hand in hazardous environments and ATEX and Ex Zones.

This non-sparking torque wrench is available in Copper Beryllium (CuBe) only.

For more information on our non-sparking torque wrench or other items, please contact one of our experts at 1-800-700-5919.

- Standard Sizes

- ALLOYS & USE

| Magnetism | No. | Drive inch | l inch | Torque Range ft./lbs. | Wt. lbs. | l mm | Torque Range Nm | Wt. kg |

|---|---|---|---|---|---|---|---|---|

| Slight Magnetism | Ex1401TB-B | 1/2 | 20-1/2 | 22-110 | 3 | 521 | 30-150 | 1.38 |

| Non-Magnetic | EX1401NM-B | 1/2 | 20-1/2 | 22-110 | 3 | 521 | 30-150 | 1.38 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details