MAB 825 KTS Portable Magnetic Mill Drill

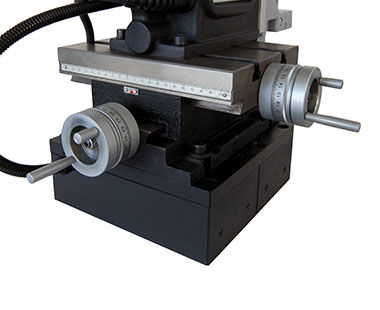

Versatile machine with adjustable X and Y positioning

Features:

- Red Dot 2021 Product Design Award Winner

- Ideal for drilling & milling

- Drill up to 3-1/8” dia. holes

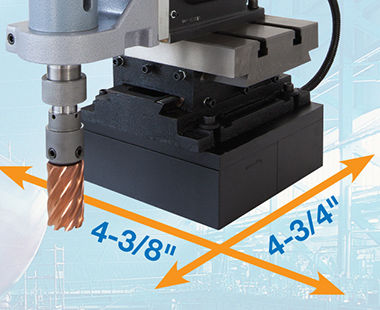

- Portable x,y cross table base for dynamic hole drilling and milling

- 4-3/8” (110mm) in x-axis, 4-3/4” (120mm) in y-axis

- Reversible motor – tap up to 1-3/16” dia.

- Internal Lubrication for increased cutting tool life

- Variable Speed & Torque

- Overheat protection

Max. Hole Dia. | Twist Drill Dia. | Tapping Dia. | Power | Speeds | Options |

|---|---|---|---|---|---|

| |||||

Ø 3-1/8" | Ø 1-1/4" | Ø 1-3/16" | 16 Amp 110 Volt | 40-110 65-175 140-360 220-600 RPM | Multi-axis positioning - adjustable up to 4-3/4" forward/backward and 4-3/8" left/right after magnet is adhered to surface. |

Benefits:

- Variable speed and torque allow for increased cutting tool life and reduced operating cost

- Included carrying case with transport wheels allows for easy portability

- Morse Taper 3 spindle for easy changeout to a wide range of tool holders with included chuck collet tool holder set (ZSF 316)

- Large capacity (3-1/8” dia.) and Large stroke (10”) to fit a wide range of milling and drilling applications

- CoolMag™: Magnet overheating protection for reduced tool wear

- Streamlined, ergonomic arrangement of controls for easy operation

- Servo assisted drilling for reduced fatigue and consistent feed pressure

Safety

- Emergency-off function: electronic safety sensor shuts down drill motor if magnet loses contact with material to protect operator and equipment

- SafeMag™: Green/Red LED magnetic force indicator for safe operation

- Up to 6,600 lbs of magnetic holding force

Learn more about the special features and integrated safety of our magnetic drill line.

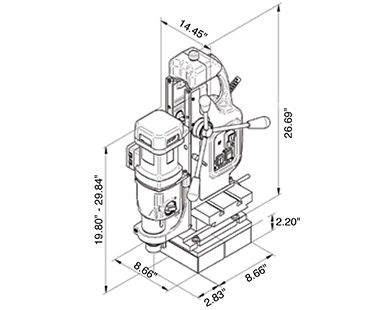

- MAB 825 KTS Specs

- Video

- Standard Equipment

- ZSF 316 Chuck Collet Tool Holder Set

| Motor Power | 16 Amp / 110 Volt |

|---|---|

| Weight | 99 lbs. |

| Stroke | 10" |

| Hole Capacity | 3-1/8" dia. |

| Twist Drill Capacity | 1-1/4" dia. |

| Tapping Capacity | 1-3/16" dia. |

| Milling Capacity | up to 5/8" dia. at 1" depth |

| Speeds | 40-110, 65-175, 140-360, 220-600 RPM |

| Magnet Base Size | 8-11/16" L x 8-11/16" W |

| Dimensions | 19-3/4" H x 13" L x 14-1/2" W |

Magnetic Force (1" plate) | 6,600 lbs. |

| Arbor Bore | 3/4" and 1-1/4" standard |

| Spindle | MT3 |

| Automatic Lubrication | Included |

| 1 Magnetic drilling machine |

| 1 Steel carrying case† |

| 1 Safety chain |

| 1 Drift key MT3 (Order No. 5301) |

| 1 ZSF 316 Chuck Collet Tool Holder Set |

| 1 Operating manual |

| 1 Warranty certificate |

Standard Equipment also includes auto lubrication, safety strap, carbin hook and allen keys. † Steel case intended mainly for shipping purposes; damage may occur in transit |

| Optional 3/4" geared chuck available - Part No. IBC 21 |

| The MAB 825 KTS magnetic drill includes a Chuck Collet Tool Holder Set with Case (p/n ZSF 316). This kit can hold most standard end mill shanks from 1/8" to 5/8" (3mm to 16mm) dia. The kit includes:

|

| SHORTCUTS: | DOWNLOADS: |

|---|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details