Protect Workers from Hand-Arm Vibration Syndrome with Low-Vibration Tools

Operators of hand-held power tools such as scalers, grinders and impact wrenches are at high risk of vibration-related injuries. Routine exposure to vibration – even for short periods can cause severe damage to blood vessels, nerves, muscles and joints in the hands, wrists and arms.

Before you dismiss those risks as hearsay, consider this: one expert has estimated that 2 million workers in the U.S. are exposed to hand-arm vibration, and as many as half of those will develop “HAVS” Hand-Arm Vibration Syndrome.[1] Symptoms range from tingling, numbness and pain to loss of color in the fingers (“blanching”) and weakened grip from nerve and blood vessel damage. With continued exposure over time, the effects can become irreversible.

Fortunately, HAVS is also entirely preventable. With the right tools and some basic mitigation strategies, workers can be highly productive on the job site while also being shielded from dangerous vibration exposure levels.

Limits on Vibration Exposure

Both ANSI (ANSI/ASA S2.70) and European Union (Directive 2002/44/EC) standards set maximum daily exposure limits based on the amount of vibration generated by a tool and the trigger time per day/shift. Exposure is measured in meters per second squared of vibration acceleration.

- Maximum cumulative daily exposure is 5 meters/second2 of vibration acceleration for an 8-hour time-weighted average workday.

- Monitoring and controls are mandated above 2.5 meters/second2 of exposure, requiring companies to examine the cause and prevent exposure.

What does that mean on the job site? Here are some examples of the maximum exposure time for different levels of vibration.[2] In more extreme cases, the Exposure Action Value can be reached in as little as 10 minutes when using conventional high-vibrating power tools.

| Exposure | Maximum Time of Exposure |

|---|---|

| 2.0 m/s2 | 12 hours |

| 2.5 m/s2 | 8 hours |

| 3.5 m/s2 | 4 hours |

| 5 m/s2 | 2 hours |

| 7 m/s2 | 1 hours |

| 10 m/s2 | 30 min. |

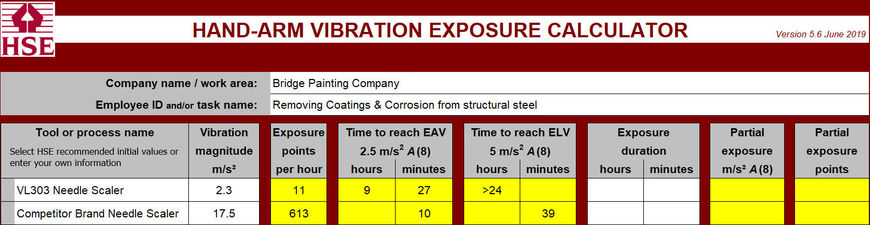

The UK Health and Safety Executive agency (HSE) provides a hand-arm vibration calculator for download on its website.

The EU directive is often cited internationally. The U.S. Army references the same exposure limits in its Vibration Pocket Guide for Prioritizing Hand-Arm Vibration.[3] And The National Institute for Occupational Safety and Health (NIOSH) recognized the vascular and neural risks of vibration exposure nearly four decades ago. It recommended that “jobs be redesigned to minimize the use of vibrating hand tools, and that powered hand tools be redesigned to minimize vibration.”[4]

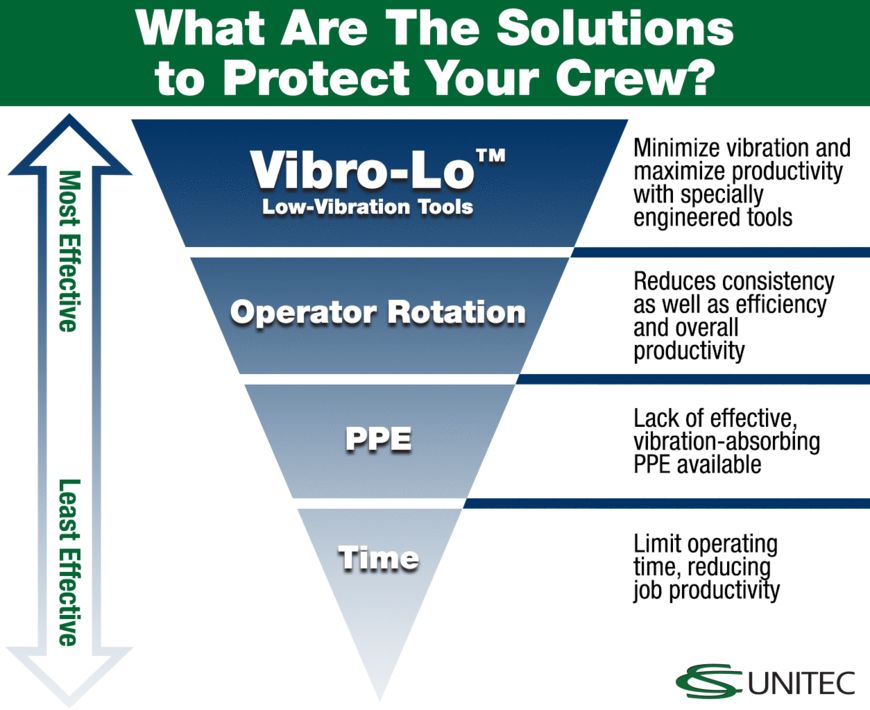

How Can You Protect Your Crew?

There are various strategies you can take to prevent workers from reaching dangerous levels of vibration exposure during a given shift. Below we provide a range of measures and their overall effectiveness.

The Best Answer for a Productive, Safe Jobsite: Low-Vibration Tools

Vibro-Lo™ series and reduced vibration tools from CS Unitec were engineered specifically to reduce vibration and allow operators to work safely for longer periods of time, maximizing productivity. These tools use a special vibration reduction system to isolate the tool body by neutralizing the recoil and impact energy between internal components. Vibro-Lo models generate up to 8x less vibration than standard tools.

Using Vibro-Lo tools, workers can typically complete an entire 8-hour shift without reaching recommended vibration exposure limits. In this example, an operator who previously reached their exposure threshold in just 10 minutes using a conventional needle scaler could work for nearly 9.5 hours with a Vibro-Lo scaler. The low-vibration scaler also gets the job done far more quickly, covering 8m2 per hour versus 4.5m2 per hour with a conventional tool.

CS Unitec can outfit your crew with a wide range of low-vibration and vibration reduced tools, including:

- Needle Scalers and Chisel Scalers: for texturing and removal of coatings, rust, and adhesive on concrete and metal

- Concrete Scabblers: to roughen, reduce and level concrete surfaces to prepare for coatings and finishes; plus pole scabblers for hard-to-reach applications

- Pneumatic Tampers: quickly compact backfill, asphalt patching and more

- Hand-Held and Floor Concrete Grinders: reduce, remove and smooth concrete surfaces

- Scaling Hammers and Deck Scalers: for removal of coatings and corrosion

Other Advantages of Low-Vibration Tools:

The advanced engineering required to reduce vibration to these levels brings additional benefits to users of Vibro-Lo (low-vibration) tools:

- Enhanced ergonomics for better operator comfort and increased productivity

- For air tools: reduced air consumption = run more tools from a single compressor

- Reduced decibel levels

- Fewer breakdowns

- Service kits extend operating hours and minimize costly on-site downtime

- Vacuum shrouds are available or included for working more safely with hazardous coatings and dust

- ATEX-certified models allow for safe operation in potentially explosive environments

Contact CS Unitec for more information on low-vibration tools and other measures that can protect your crew from HAVS.

References:

1 – National Safety Council / Safety+Health magazine – “Hand-arm vibration syndrome”

https://www.safetyandhealthmagazine.com/articles/13117-hand-arm-vibration

2 – Navadan white paper – “Managing hazards of HAVS”

https://www.navadan.com/our-company/latest-news/211-managing-hazards-of-...

3 – U.S. Army TG356 – Vibration Pocket Guide (PDF)

https://phc.amedd.army.mil/PHC%20Resource%20Library/TG356_VibrationPocke...

4 – NIOSH publication 83-110

https://www.cdc.gov/niosh/docs/83-110/

CDC – Criteria for a Recommended Standard: Occupational Exposure to Hand-Arm Vibration

https://www.cdc.gov/niosh/docs/89-106/89-106.pdf?id=10.26616/NIOSHPUB89106

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details