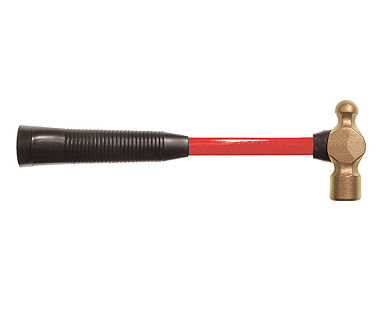

Ball Peen Hammer

Ex101U Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Hammer handle appearance may vary from photos shown.

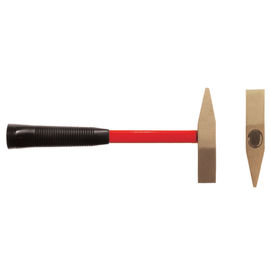

Applications:

- Non-sparking ball peen hammers for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic ball peen hammers for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant ball peen hammers for use in desalination plants, chemical/paper manufacturing, and shipyards.

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details